Callaway X Prototype Combo Iron – Japan Forged + MILLED

The X Prototype Combo Iron is an upgraded version of the already popular X FORGED irons that dropped earlier this year. Those irons were a hit, and now Callaway Japan has taken it a step further with this limited-edition set launching in August. At the time of writing this blog post we only have a few sets left.

The key thing to note is that these are Made in Japan using the gigantic enomoto press, then the raw forged single pressed head is CNC milled for it’s base shape and aesthetics. Then the rough milling marks are polished away to to complete the club. Japan Forged & CNC Milled in Tochigi Japan by Sasaki Co.

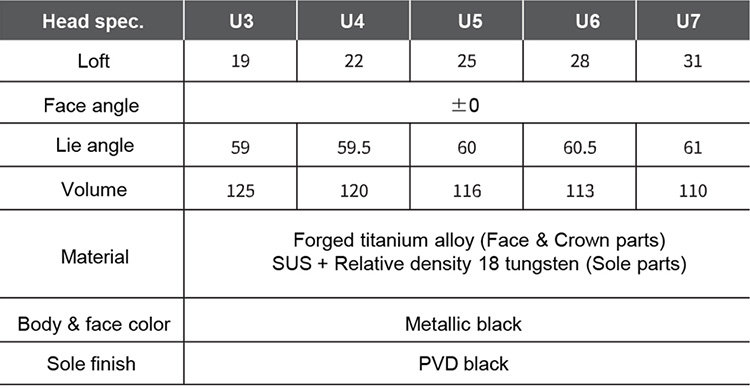

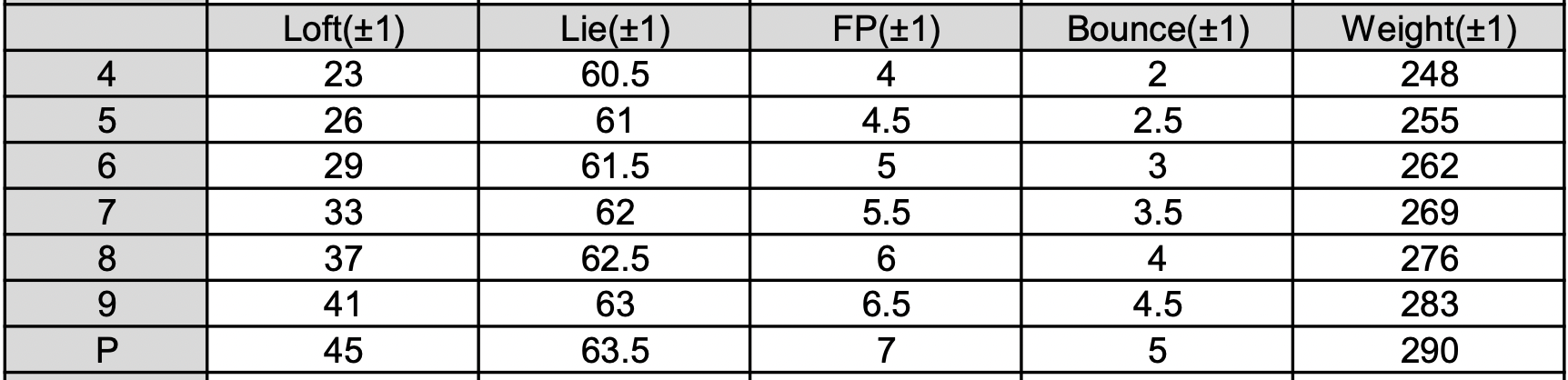

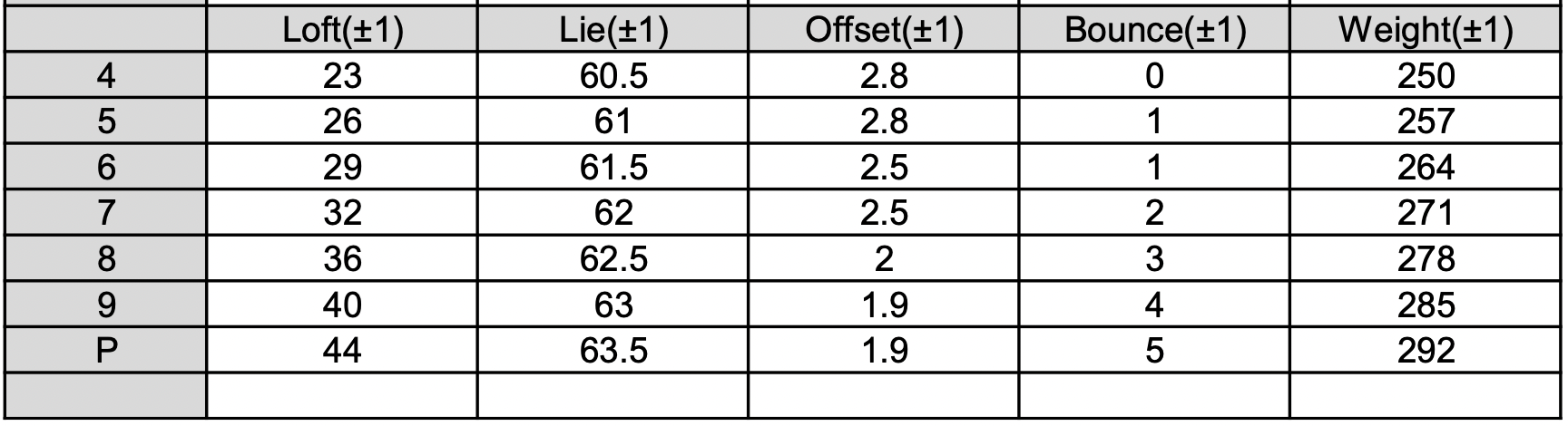

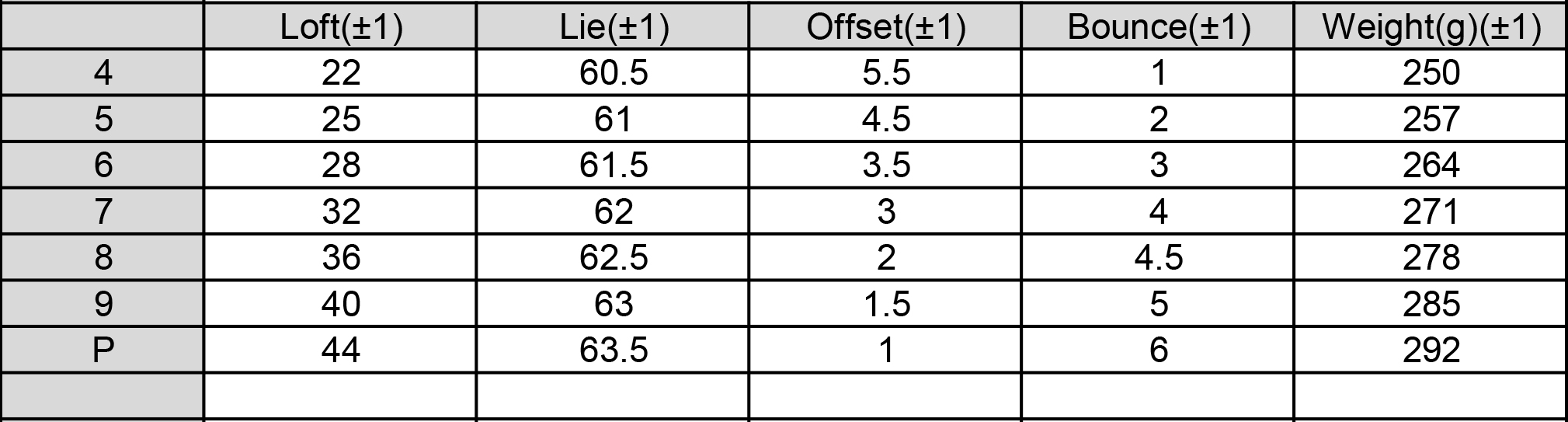

This set is a combo of 7 irons (I#4-9, PW), just like the X FORGED, with a 33-degree loft on the I#7. But what sets the X Prototype apart is the mix of head shapes. The I#4-7 are cavity back, giving you that extra forgiveness on longer shots, while the I#8, 9, and PW shift to a muscle-back design for more control when you need it.

Thanks to a unique forged + milled construction, you get an incredibly soft feel at impact. Unlike traditional methods that can harden the material, these clubs are forged with just one strike, then precision-milled to perfection. The result? A pure, soft feeling.

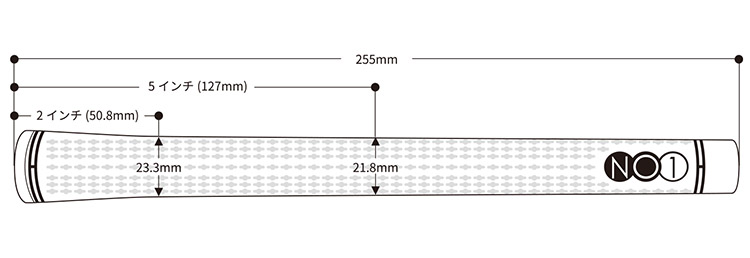

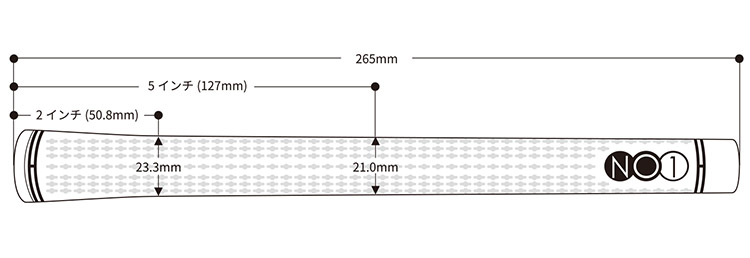

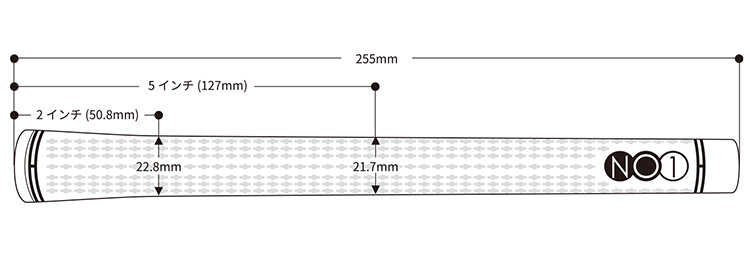

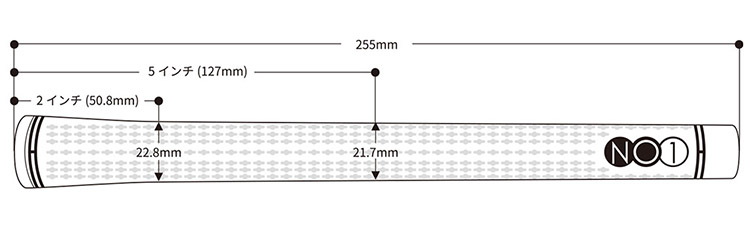

The leading and trailing edges are chamfered, and the sole width has been fine-tuned for better performance. Plus, the loft markings are smaller, giving it a sleek, refined look. Now, here’s the real kicker—every single part of these irons is made in Japan. From the forging of the head by Sasaki Corporation in Tochigi Prefecture to the assembly of the shaft and grip, it’s all done right here. That’s what makes the X Prototype truly special.